GRINDER 200-300

Pompe sommergibili trituratrici in ghisa per acque sporche, 2 poli, da 2.0HP a 3HP,

Max prevalenza: 32 m,

Max portata: 160 L/min

| Description |

The grinder pumps are provided with a cutting system able to chop up paper, little ropes, towels, napkins, leather, objects in plastic, rubber, lattex or other fibrous parts present into the sewage water. The grinding pumps are required when the delivery pipes are so narrow that a solid part could clog the pipe itself or when it is needed a pump for sewage water but with an high head. The pumps series GRINDER 200-300 must always be connected to a control box including a manual reset amperometric protection: this kind of protection is necessary to avoid that the motor can get burnt in case a too hard solid part blocks the cutting system. |

| Use |

The GRINDER 200-300 are very professional and they are usually installed in hospitals, camping, restaurants and hotels. These models cannot be used to pump water containing stones nor hard solid parts (e.g. pieces of wood or metal) nor straw. |

| Operation conditions |

Max liquid temperature: 50 °C (122 °F) pH: 6-10 Max density < 1100 kg/m³ Max immersion depth: 30m |

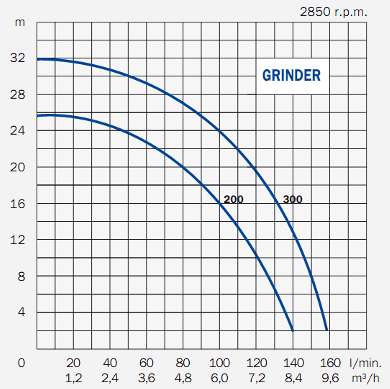

Performance curve:

| Models | Head (m) | ||||||||

| 4 | 8 | 12 | 16 | 20 | 24 | 28 | 32 | ||

| Capacity | |||||||||

| GRINDER 200 | L/min | 136 | 127 | 115 | 100 | 80 | 46 | 0 | |

| m3/h | 8,2 | 7,6 | 6,9 | 6,0 | 4,8 | 2,8 | 0 | ||

| L/s | 2,27 | 2,12 | 1,92 | 1,67 | 1,33 | 0,77 | 0 | ||

| GRINDER 300 | L/min | 156 | 150 | 142 | 130 | 119 | 100 | 71 | 0 |

| m3/h | 9,4 | 9,0 | 8,5 | 7,8 | 7,1 | 6,0 | 4,3 | 0 | |

| L/s | 2,60 | 2,50 | 2,37 | 2,17 | 1,98 | 1,67 | 1,18 | 0 | |

Technical characteristics:

| Outlet | 1"1/4 - DN 32 vertical flanged with threaded counterflange |

| Solid passage | --- |

| Cutting system | Composed by a fix cutting ring and a rotating knife |

| Impeller | Back open impeller "vortex" type. |

| Mechanical seal | Double mechanical seal in oil chamber. The lower one in silicum carbide / silicum carbide / NBR, the upper one in allumina / graphite / NBR + NBR oil seal. |

| Motor | Dry. Insulation class: F. |

| Motor protection | Automatic reset built-it thermal protection (also on the three-phase models). Anyway the pumps must be connected to a fused remote isolator switch at customer's care (see optional electric board) also for single-phase models |

| Float-switch |

The pump model GRINDER 200 (230V/50Hz/1-ph) can be supplied both with and without float-switch, the pumps models GRINDER 200 and GRINDER 300 (400V/50Hz/3-ph) are supplied without float-switch. |

| Cable |

For the single-phase version: 10 meters cable H07RNF 3G1.5 without plug; for the three-phase version: 10 meters cable H07RNF 4G1.5 without plug |

| Capacitor | Start capacitor: 100μF - 250V, running capacitor: 12μF - 450V. |

| Only for single-phase version | |

| IP | 68 |

Electric characteristics:

| Models | Power | Nos. poles | R.p.m. | Voltage | Ampere |

| GRINDER 200 | 2.0HP - 1.5kW | 2 | 2850 | 230V/50Hz/1 | 10,2 A |

| 400V/50Hz/3 | 3,5 A | ||||

| GRINDER 300 | 3.0 HP - 2.2kW | 2 | 2850 | 400V/50Hz/3 | 5,0 A |

Materials:

| Cutting system | Stainless steel AISI 440 tempered |

| Impeller | Cast-iron GG 25 |

| Pump cover | Cast-iron GG 25 |

| Motor case | Cast-iron GG 25 |

| Pump body | Cast-iron GG 25 |

| Pump support | Cast-iron GG 25 |

| Motor shaft | Stainless steel AISI 403 |

| Packing set | NBR |

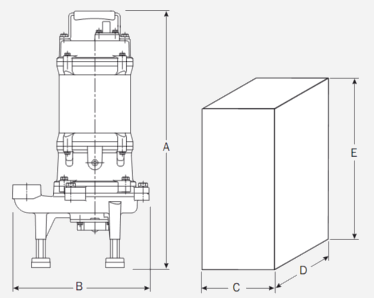

Weight and dimensions:

| Models | Voltage | Outlet | Dimensions (mm) | Weight | ||||

| female threaded | A | B | C | D | E | (kg) | ||

| GRINDER 200 | 230V/50Hz/1 | 1"1/4 - DN 32 | 597 | 285 | 270 | 250 | 680 | 36 |

| 400V/50Hz/3 | 546 | 285 | 270 | 250 | 520 | 33 | ||

| GRINDER 300 | 400V/50Hz/3 | 1"1/4 - DN 32 | 546 | 285 | 270 | 250 | 520 | 35 |

Optionals:

| Connections | Professional straight brass connection 1"1/4 in three pieces |

| No-return valve | Professional ball check valve threaded 1"1/4 in cast-iron |

| Float-switch | 10 or 20 metres cable float-switch to be connected to an electric board |

| Electric board | The models GRINDER 200 and GRINDER 300 (both single-phase and three-phase) must necessarly be connected to an electric board with an amperometric protection (as the models F5-0.5/3-1 for single-phase pumps and F6-0.5/10-3 for three-phase pumps). This kind of protection is necessary for grinder pumps to avoid that the motor can get burnt in case a too hard solid part blocks the cutting system. |

GRINDER 200-300 ITA - REV. 2.0 - 29/08/2017