WELL S12

4" submerged pumps, 2 poles, from 1.5kW to 5.5kW,

Max head: 202 m,

Max capacity: 200 L/min

| Use |

4" professional submersible pumps. Suitable for clean or slightly sandy water. These models are usually applied to pump water from 4" deep wells to give pressure to the hydraulic plant of houses or for small irrigation systems. The hydraulic part is supplied separately from the motor and the motor has only 1,7 metres cable. |

| Operation conditions |

Max liquid temperature: 35 °C (95 °F) pH: 6-8 Max density: 1000 kg/m³ Max immersion depth: 200m |

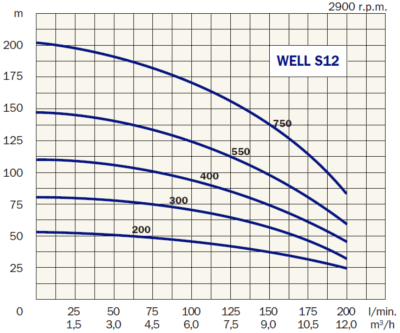

Performance curve:

| Models | Capacity | |||||||||

| L/min | 0 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | |

| m3/h | 0 | 1.5 | 3.0 | 4.5 | 6.0 | 7.5 | 9.0 | 10.5 | 12.0 | |

| L/s | 0 | 0.42 | 0.83 | 1.25 | 1.67 | 2.08 | 2.50 | 2.92 | 3.33 | |

| WELL S12 200 | Head (m) | 53 | 52 | 50 | 48 | 43 | 41 | 37 | 31 | 25 |

| WELL S12 300 | 81 | 80 | 78 | 75 | 69 | 64 | 57 | 45 | 33 | |

| WELL S12 400 | 110 | 109 | 107 | 100 | 94 | 85 | 74 | 61 | 44 | |

| WELL S12 550 | 148 | 146 | 140 | 133 | 124 | 113 | 98 | 80 | 60 | |

| WELL S12 750 | 202 | 197 | 191 | 181 | 169 | 156 | 137 | 113 | 83 | |

Technical characteristics:

| Models | WELL S12 200 | WELL S12 300 | WELL S12 400 | WELL S12 550 | WELL S12 750 |

| Number of stages | 8 | 13 | 17 | 23 | 32 |

| Outlet | 2" - DN 50 threaded | ||||

| Axial thrust | 2000 N | 3000 N | 5000 N | ||

| Motor |

Oil bathed, rewindable. Insulation class F. Available also water bathed motor. |

||||

| Motor protection | To be provided into an external control box (see optional) | ||||

| Mechanical seal | In graphite / ceramic / NBR | ||||

| Float-switch | The pumps are supplied without float-switch | ||||

| Cable | 4G1.5 | 4G2 | |||

| 1,7 meters cable without plug approved KTW, ACS and WRAS | |||||

| Capacitor | 60μF - 450V | - | |||

| Only for single-phase motors. To be installed into an external control box (see optional) | |||||

| IP | 68 | ||||

| Max content of sand | 40 gr/m3 for the motor, 180 gr/m3 for the hydraulic part | ||||

Electric characteristics:

| Models | Power | Nos. poles | R.p.m. | Voltage | Ampere |

| WELL S12 200 | 2.0HP - 1.5kW | 2 | 2900 | 230V/50Hz/1 | 10,6 A |

| 400V/50Hz/3 | 4,8 A | ||||

| WELL S12 300 | 3.0HP - 2.2kW | 2 | 2900 | 400V/50Hz/3 | 6,2 A |

| WELL S12 400 | 4.0HP - 3.0kW | 2 | 2900 | 400V/50Hz/3 | 8,6 A |

| WELL S12 550 | 5.5HP - 4.0kW | 2 | 2900 | 400V/50Hz/3 | 8,9 A |

| WELL S12 750 | 7.5HP - 5.5kW | 2 | 2900 | 400V/50Hz/3 | 11,7 A |

Materials:

| Hydraulic part | Impellers | Noryl |

| Diffusers | Glass filled polycarbonate | |

| External case | Stainless steel AISI 304 | |

| Suction grid | Stainless steel AISI 304 | |

| Discharge head | Stainless steel AISI 304 | |

| Coupling flange | Stainless steel AISI 304 | |

| No-return valve | Built-in, in stainless steel AISI 304 | |

| Motor | External case | Stainless steel ASI 304 |

| Upper flange | Stainless steel ASI 304 | |

| Shaft | Stainless steel ASI 304 |

Weight and dimensions:

| Models | Outlet | Voltage | Dimensions (mm) | Weight (kg) | |||||

| D | Lm | Li | Lt | Motor | Pump | Total | |||

| WELL S12 200 | 2" - DN 50 | 230/50/1 | 98 (4") | 474 | 418 | 854 | 11,7 | 4,0 | 15,7 |

| 400/50/3 | 424 | 804 | 10,2 | 14,2 | |||||

| WELL S12 300 | 2" - DN 50 | 400/50/3 | 98 (4") | 474 | 573 | 1009 | 11,7 | 5,5 | 17,2 |

| WELL S12 400 | 2" - DN 50 | 400/50/3 | 98 (4") | 543 | 697 | 1202 | 15,0 | 6,6 | 21,6 |

| WELL S12 550 | 2" - DN 50 | 400/50/3 | 98 (4") | 647 | 921 | 1530 | 20,1 | 8,4 | 28,5 |

| WELL S12 750 | 2" - DN 50 | 400/50/3 | 98 (4") | 737 | 1238 | 1937 | 24,7 | 11,0 | 35,7 |

Optionals:

| No-return valve | No-return check valve 2" |

| Cable junction kit | In resin or thermo-contracting |

| Additional cable | The section of the cable depends on the lenght needed and the power of the motor |

| Control box |

Series L1 just for pump starting |

|

Series F5 (for single-phase motors) or F6 (for three-phase motors) that permit the connection of controls (float-switch, sounding probe, pressure switch) |

|

| Sounding probes |

To avoid dry running |

| Pressure system set | Presscontrol |

| Manometer, pressure switch and expansion tank |

WELL S12 ENG - REV. 2.0 - 29/08/2017